Somewhere down the track, you may need to make something to a particular size. And knowing that clay shrinks quite a bit, it is vital to know precisely how much and when in the process the shrinkage happens.

Traditional and online methods to estimate dry-to-fired shrinkage

Clay shrinks due to water loss, as well as physical and chemical changes during drying and firing.

This shrinkage is usually expressed as a percentage of the wet size and is typically between 5% and 20%.

Most clay manufactures will have data sheets showing typical shrinkage rates, sometimes expressed as a single wet-to-fired figure, other times as wet-to-dry percentage, bisque shrinkage percentage and firing percentage for various temperatures.

Testing – the surest method

We need at our fingertips some clay “rulers” to measure the particular size needed.

To make a ruler

- Roll, flatten or cut the ‘soft’ clay so that the thickness is between half and one cm thick. About the thickness of the wall of a vessel.

- Cut a strip approximately a ruler width or wider, about 12cm long.

- Scratch a fine line down the centre 10cm long exactly, and mark each cm (and better) each half cm along the length of the line.

- Scratch on the front or back the name of the clay, whether it is ‘soft’ or ‘leather-hard’, and what temperature it is going to be fired to. The date is also good as manufacturers change the blend from time to time.

Essential Records

- Measure when bone dry and record the difference. Let’s say it is 8mm shorter. That’s 8mm in 100mm or 8%. You can write this in colour on the bar for future reference.*

- Bisque fire and measure again. It will probably only have shrunk another 1mm, if that.

- Gloss fire and record the final shrinkage. Let’s say it’s another 7mm shorter. Total of 15mm shorter than ‘soft’ and therefore a total shrinkage of 15%.

Now you have your clay ruler – see this example from US potter, Jan MacKay

Note: Clays continue to shrink as the kiln temperature increases because some of the particles begin to melt and form a glass that pulls them even closer. With higher temperatures, clay eventually shrinks to a maximum point after which swelling occurs as a precursor to melting.

So for greater accuracy, it is important to know the firing temperature pretty exactly! This fact can be used to some advantage if, for instance, a lid is a bit tight on a container, it can be refired to a slightly higher temperature at which it will shrink a tiny bit more.

How to use the ruler:

Measure the size that needs to be matched WITH THE SHRUNKEN RULER. Let’s say 8.5cm.

When making the clay item measure it with a NORMAL RULER. 8.5 on normal will shrink to 8.5 on the clay rule. Give or take a bit!

It is handy to have a shrinkage bar for all the clays you are using in your studio, in all the various stages of wetness, usually three. That is: straight off the block, wet after being thrown, or leather-hard.

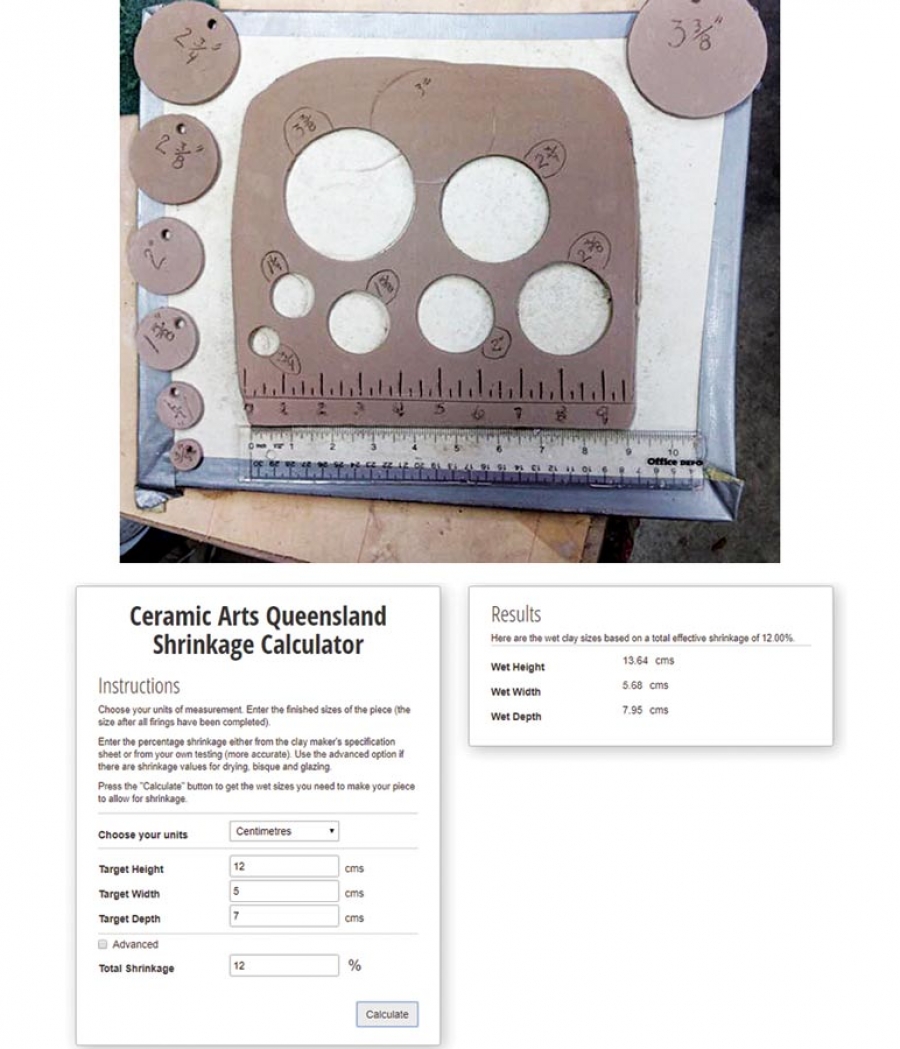

Ceramic Arts Queensland’s Online Shrinkage Calculator

The clay ruler takes into account all of the variables for clays, drying and firing conditions that apply in your studio.

However, if you want to get an estimate of shrinkage, then our new online shrinkage calculator will be useful.

You can find it on our main website under the Tools dropdown menu.

How to use the calculator

You first need to find out the shrinkage percentage for your clay at your firing temperature. You do this by looking up the data-sheets from the manufacturer or by talking with your clay supplier.

Open up the CAQ shrinkage calculator page and enter in the FINAL dimensions you want the finished piece to be and the shrinkage percentage.

If the datasheet gives a single figure enter that directly. If it gives two or three percentages for the various stages, click the advanced button and enter them.

The calculator will do the math to get the wet sizes for you to make the piece so that when it shrinks, it will be the size you want – or there-about!

No online system will be more accurate than actually using a clay ruler that has been dried and fired in the way your actual piece will be treated, but the calculator will give you a very approximation or can be used as a basis for further testing.

The online calcualtor main benefit is immediacy. The Ceramic Arts Queensland’s online calculator will give you a good estimation immediately, where-as making a shrinkage ruler may take several days.

*If you know what the dry (pre-fired) shrinkage is you can check the dry measurement of the special piece for accuracy before you fire it.