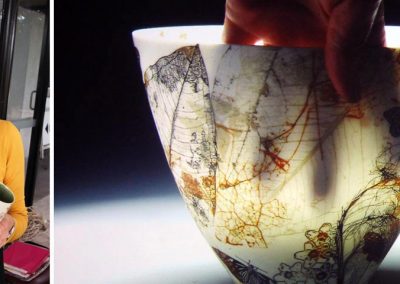

We were very fortunate to have Mollie Bosworth talk about her stunning decorative techniques, for while she has been using and experimenting with mineral salts for many years, she has been reluctant to do workshops due to the toxicity of the materials and the unpredictable results.

As levels of toxicity vary, some being carcinogenic, it is imperative that users know the health and safety recommendations for handling these substances. With these concerns a priority Mollie gave the following tips for working with these materials:

- There may be no smell – so wear a mask.

- Good ventilation required.

- Advisable to wear gloves. (Each salt has its own Health & Safety requirements.)

- Mix small quantities for easier (safer) handling.

- Keep tools separate from other tools.

- Work on newspaper to absorb spills.

- Throw sponges and cotton buds away.

- When firing, avoid fumes. Good kiln venting required in urban areas.

Mollie was introduced to this process in a very old book, which is now difficult to find. A request to a library may locate a copy for borrowing. Written by Norwegian ceramic artist Arne Ase, “Watercolours on Porcelain” is an essential reference and includes health and safety tips on each material.

Also reference the work of:

Mark Goudy & Liza Riddle (California), John Shirley (South Africa), Angela Mellor (Australia/UK), Luca Tripaldi (Italy), Piet Stockmans (Belgium), Astrid Gerhartz (Germany).

The colourants that Mollie spoke about included:-

- Iron chloride

- Cobalt chloride or safer option Cobalt sulphate

- Gold chloride

- Copper chloride or Copper sulphate

- Copper oxychloride

- Potassium dichromate or Potassium chromate – both toxic and may cause cancer.

Some of these are available in garden sections of good hardware stores, while others can be purchased online from chemical suppliers. Usually, the dry or crystalline materials dissolve fully or partially in water, but some require Hydrochloric acid, and gold needs a combination of two acids, termed aqua regia, to dissolve.

As with our basic colouring oxides, these salts look different in different concentrations and work a bit like watercolours. Having obtained the strongest concentration from dissolving a salt in either water or acid, they can be diluted with water to give weaker effects or left to become stronger after evaporation.

Mollie prepared several samples by dividing up areas on thin bisque white clay tiles using a resist liquid, Liquitex* or Latex**. She decorated both moist and dry tiles.

(Apply the resist with cotton buds and throw away, or dip brushes in detergent first for easy cleaning.)

The colourant solution was brushed on horizontally so that areas of single, double, and triple coatings were separated by resist lines.

The acid** was brushed on vertically, over the bands of colour, and we watched the acid displace the colourants. The degree of dampness of the bisque is critical, as moistness encourages diffusion.

We also observed that:

- Some colours were sucked into the bisque and almost disappeared. Hence the suggestion that if food colourant is added to the mixes, you can see where it has been brushed.

- On damp tiles, the colourants seeped under the latex boundaries and created a halo effect.

- This was less apparent on dry tiles. Mollie dries them in a warm place to make sure they are completely moisture-free if the boundary is to be as crisp as possible.

- The clay was whitest under the latex, less white under the acid, grading to full colourant saturation.

- Over time, a few hours or more, the colourants seep right through the thin clay to the other side.

- Some colourants, like gold, for instance, may seep in completely and not be visible.

- Others, like potassium, disappear but on drying become visible again.

*Liquitex is a gloss medium/varnish available from Art Suppliers, Bunnings, etc. Liquitex is water-soluble, it can be diluted and used as a resist material.

**Latex is also a wax substitute and water-soluble while still liquid.

Another decorative idea shown by Mollie is the technique known by many names, whereby the resist material is applied to raw ware (leather-hard or bone dry) and when the resist is dry the un-masked surface is eroded by repeatedly sponging with a damp sponge to remove areas of raw clay, leaving the resisted areas proud of the surface, in relief. Extension: Apply more resist and repeat to build up a 3D look and vary the translucency – apply up to 3 times. Variation: apply oxide/underglaze to the surface before the resist.

The resist can be peeled off before firing using a scalpel or pin, which enables mistakes to be peeled off too.

** Acid is Phosphoric – 85% food-grade, used to clean commercial kitchens and brewing equipment – watered down. Work with small quantities for ease and safety.

Additives to colourants and acid

- CMC from ceramic suppliers or diluted wall-paper paste can be added to acid and colourants to encourage them to stay on top of bisque rather than soak in, especially if using gold.

- Wallpaper paste, the light-weight version, can be purchased in small packets. The powder takes about 30 minutes to dissolve in water and go clear.

- Food colourants may be added so you can see where they have been brushed.

General tips

Store liquids in small lidded glass jars with labels.

The salts can be blended for more colour options. If applying one over another, it makes a difference which one is on top. Bisquing between applications may be helpful.

Mollie bisques Southern Ice porcelain to 1000˚ and polishes with diamond pads, grades 120, 240, and 400.

Mollie concluded this part of her demonstration with words of encouragement to test anything that comes within your reach, or go seek unusual materials, rare-earths for instance, to see what they can reveal.

Decals

The simplest type of decal is a ‘waterslide laser decal’ printed on a printer where the black ink (toner) contains iron. Mollie uses generic ink cartridges in a basic black (not colour) HP printer.

Finding decal paper got a little more complicated in recent years after the US supplier Bel Decal was put out of business following a successful patent application over the laser decal process.

However, Mollie has tracked down an Australian source, Dr Decal and Mr Hyde, who sells the original paper now called “Bel-type decal paper”. A list of other suppliers below.

A waterslide laser decal is a one-colour decal, black that fires brown. As we know from using iron oxide, when put with a clear glaze, the glaze “eats” the iron, it goes very pale or disappears.

So Mollie uses these decals on bisque ware with no glaze and fires to 1300˚C.

She suggests it may be possible with care to apply decal to a fired glaze and refire to just the temperature at which the glaze begins to soften, perhaps around cone 04 – 1060˚.

It can be tricky to get just the right temp at which the iron will stay on the surface and not get consumed by the glaze as it melts.

Mollie confirmed that Johanna is developing a paper with a flux in the cover coat so that the iron-bearing toner fuses onto the glaze at a much lower temp, like 800-830˚.

Normal decal paper result is dullish, matte colour, while fluxed paper is slightly glossy.

The images

The images for the decals can be created with any image managing software. If you don’t have Photoshop or similar, you can download Gimp for free.

Fill the page with images; duplicates, smaller, larger, leaving just a few millimetres between.

Photographs work well too.

Notes

Plain colour decal paper can be used for flat areas of colour or printed on.

Ready-made decal designs called “Open Stock” are available. Bailey Decal (UK) sells packs.

Your own designs can be digitally printed: A3 sheet ($60) John Stewart (NSW), Decal Specialists, Northcote, VIC., and Johanna DeMaine can source screen-printed decals in quantities of 10 A3 sheets from Japan

Sources for clear waterslide

Laser Decal Papers

- https://drdecalmrhyde.com.au/shop/waterslide-decal-paper-firing-bel-type-laser-printer-a4/ This is the same as the original Bel decal paper.

- https://drdecalmrhyde.com.au/shop/thick-23micron-waterslide-decal-paper-laser-printers-a4-clear/ This one also works well.

- https://decalspecialists.com.au/ A very thin decal paper, very difficult to use.

- http://fired-on.com/ This is the patent holder of the laser decal process in the USA. Very expensive paper.

Low-fire (fluxed) laser decal paper, and coloured sheet decal paper

Open Stock Decals